by 联达 | Dec 14, 2016 | Technical

Open-die forging can produce forgings from a few pounds up to more than 150 tons. Called open-die because the metal is not confined laterally by impression dies during forging, this process progressively works the starting stock into the desired shape, most commonly...

by 联达 | Dec 6, 2016 | Technical

The drive shaft — also known as the propeller (prop) shaft or cardan shaft — is the component in a vehicle that transfers the torque from the engine to other parts of the drive that cannot connect directly to the engine due to distance or other reasons. Generally,...

by 联达 | Nov 30, 2016 | Technical

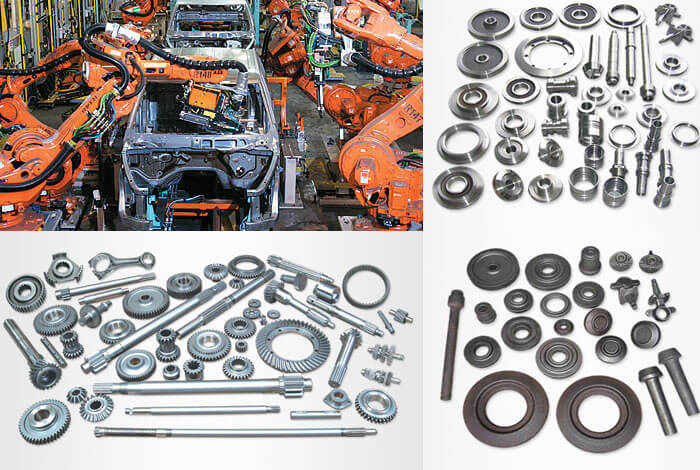

Bevel gears are gears that have intersecting axes and tooth-bearing faces that are conically shaped or tapered. The number of teeth on the mating gears need not be equal. While they can be used to transmit power, bevel gears are usually used to transmit motion,...

by 联达 | Nov 26, 2016 | Technical

Around Asia, ‘Made in China’ no longer means cheap or shoddy TAIPEI, TAIWAN — The “Made in China” brand has long stood for quantity not quality, for a low price rather than a top notch product. But that is beginning to change. After decades of producing...

by 联达 | Nov 22, 2016 | Technical

Gears are a crucial part of many motors and machines. Gears help increase torque output by providing gear reduction and they adjust the direction of rotation like the shaft to the rear wheels of automotive vehicles. Here are some basic types of gears and how they are...

by 联达 | Nov 18, 2016 | Technical

Forging is a one type of manufacturing process. In this process, including pressing and heating a metal at a very warm temperature into stronger parts. There are lots of equipment are utilized in these types of process. upsetters as well as presses are the equipments...

by 联达 | Nov 11, 2016 | Technical

FLANGE TYPES As already described before, the most used flange types acc. to ASME B16.5 are: Welding Neck, Slip On, Socket Weld, Lap Joint, Threaded and Blind flange. Below you will find a short description and definition of each type, completed with an detailed...

by 联达 | Nov 4, 2016 | Technical

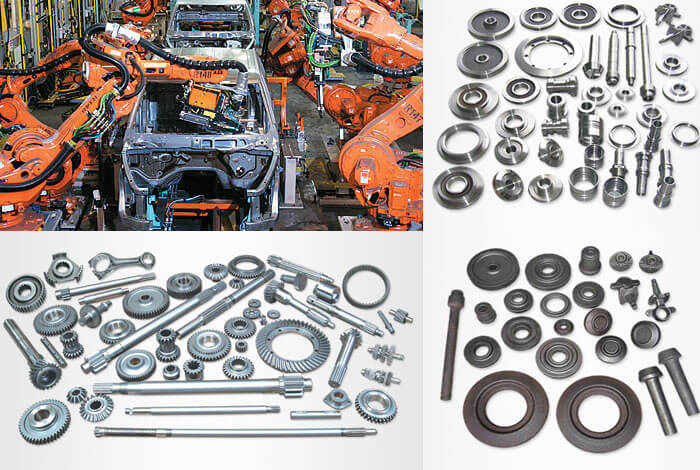

The forging process can create parts that are stronger than those manufactured by any other metalworking process. This is why forgings are almost always used where reliability and human safety are critical. But you’ll rarely see forgings, as they are normally...

by 联达 | Oct 25, 2016 | News

18T(450 kj) die forging hydraulic hammer designed by Anyang forging press, adopts full hydraulic pressure drive, compared with the traditional hydraulic hammer has the following advantages: 1, Stop “mix” of oil and gas. 2, Return speed is fast. 3, The...

by 联达 | Oct 19, 2016 | Technical